+86 18510839837 / +86 13608550008

mio_weng@hotmail.com / bron2000@live.cn

Why B4C?

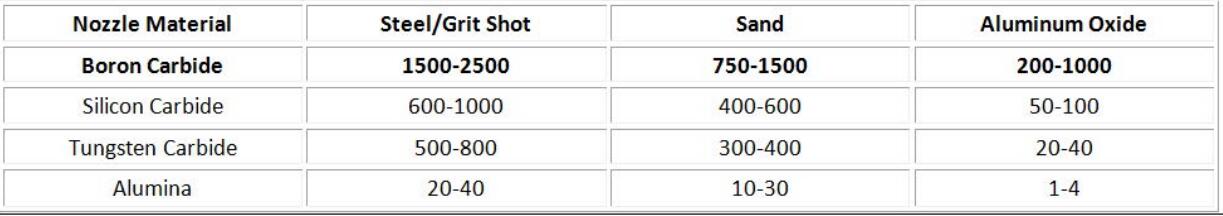

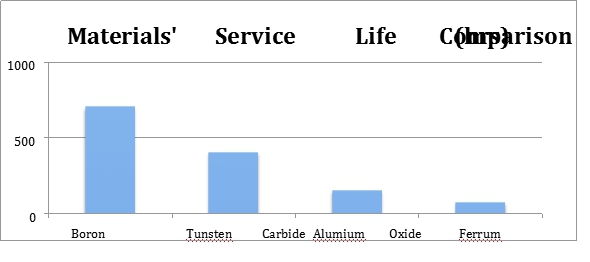

Boron carbide (B4C) sandblasting nozzles provide the longest lifetime compared with tungsten carbide, aluminum oxide and ferrum etc. other materials. Boron carbide material is 5 to 10 times more Wear-resistant compared with tungsten carbide and 3 to 5 times more with silicon carbide.

If spraying aluminum oxide as medium, Muyee’s boron carbide nozzles normally can be used about 600 hours, which is quite competitive in the global sandblasting nozzle market.